[ad_1]

A producing firm is simply pretty much as good as its gear. However extra importantly, how effectively the group makes use of its gear. With out realizing the general gear effectiveness (OEE) of manufacturing machines, corporations threat dropping floor in a hyper-competitive manufacturing surroundings.

By capturing and analyzing OEE knowledge, customers can higher perceive how successfully their gear is getting used, which is extremely necessary given the big capital expenditure that gear represents.

An OEE dashboard can show not solely the real-time OEE of a store ground, but in addition establish tendencies, patterns, and paths for enchancment, giving producers an opportunity to enhance effectivity as a part of their steady enchancment initiatives.

What’s an OEE Dashboard?

An OEE Dashboard is a manufacturing reporting function that shows real-time OEE scores for simply accessible consumption throughout the store ground.

Visible OEE dashboards are populated with OEE scores primarily based on store ground knowledge that has been collected, standardized, and contextualized.

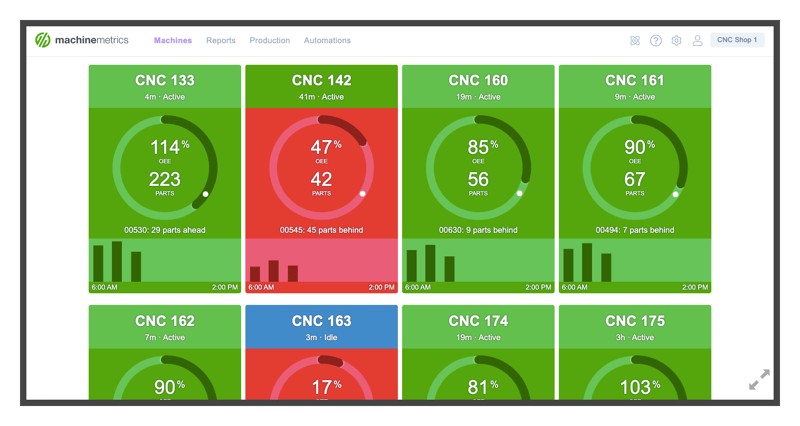

MachineMetrics OEE dashboards permit end-users to trace shift progress, establish areas of poor machine efficiency, and monitor machine situations.

An OEE Dashboard from MachineMetrics exhibits gear efficiency towards pre-defined objectives.

An OEE Dashboard from MachineMetrics exhibits gear efficiency towards pre-defined objectives.

Overall Equipment Effectiveness (OEE) is outlined because the period of time a producing machine is really productive. It combines three distinct metrics – availability, efficiency, and high quality – to attain a rating representing a machine’s precise productive time. This helps operators, technicians, managers, and higher administration make higher selections for optimized efficiency.

By displaying these situations as an OEE dashboard, HMI, or distant terminal, end-users can analyze numerous elements akin to shift or machine sort. They’ll additionally have a look at operational effectivity throughout many machines, analyze effectiveness between operators, or have a look at your complete manufacturing unit at a meta-level.

These digital manufacturing dashboards permit contextualized human-centric knowledge to be added on the level of use. As well as, they can be utilized with different analytics dashboards to evaluation knowledge facet by facet for knowledgeable decision-making, whether or not you’re on the store ground or again workplace.

Why Observe OEE Visually?

OEE dashboards are required to eradicate the danger of human error and time delays, making certain that gear is being utilized to satisfy manufacturing objectives. To seize OEE extra successfully, machine knowledge platforms like MachineMetrics seize knowledge immediately from the management of the machine. This ensures that the manufacturing knowledge is real-time, correct, and standardized throughout all makes and fashions of apparatus.

With knowledge collected and contextualized, it may be displayed on intuitive OEE dashboards to allow a real-time have a look at efficiency. This ensures full visibility of the store ground for operators, managers, and executives.

By permitting customers to shortly evaluation elements akin to downtime, manufacturing, and different variables, insights affecting high quality and effectivity will be consumed on the level of use. And motion will be taken instantly to resolve points or forestall them altogether.

Listed here are a number of areas the place an OEE dashboard is required:

OEE Over Time

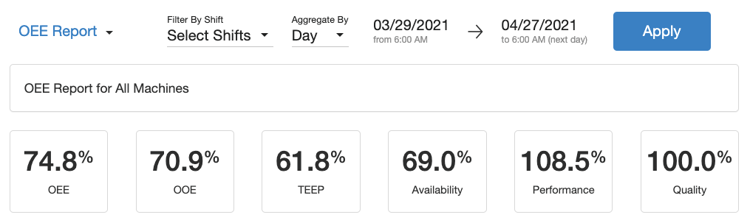

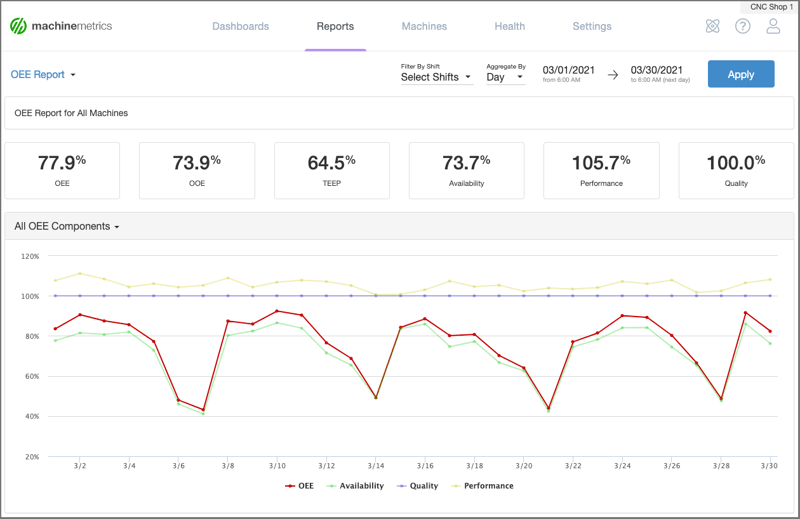

An OEE dashboard permits corporations to trace OEE over time. Human exercise in machine operation can affect high quality, downtime, and operational effectivity. Utilizing OEE dashboards and stories to trace efficiency over time signifies that managers can have a look at completely different ranges of OEE by the hour, shift, day, week, or another time-frame desired.

A MachineMetrics OEE Report displaying key metrics in addition to historic OEE efficiency.

A MachineMetrics OEE Report displaying key metrics in addition to historic OEE efficiency.

Low OEE on any of those intervals might help managers perceive downtime causes, higher direct upkeep departments, and optimize manufacturing processes to considerably enhance their OEE. As a result of manufacturing is enormously sophisticated in any manufacturing firm, the aptitude to observe OEE graphically or via an OEE report could make an enormous distinction in bettering efficiency.

OEE With Different Metrics

Sturdy machine knowledge platforms like MachineMetrics permit OEE dashboards for use alongside different dashboards to remodel insights akin to efficiency, elements objectives, and different essential metrics. The insights delivered are extra correct than human-centric metrics.

This performance is constructed into the dashboard view and enhances customers’ decision-making. Customers can shortly choose between OEE and different dashboards shortly. They’ll additionally zoom in to an in depth view or out to a high-level view of machine groupings or your complete manufacturing unit.

This may be useful for figuring out areas of alternative, akin to under-utilized gear, extreme downtime, or bottlenecks in manufacturing processes.

Machine efficiency will be color-coded on all metrics to maintain operators updated on progress towards established objectives. This might help encourage wholesome operator competitors. Easy colour schemes of inexperienced, orange, and pink permit additional visible cues and show OEE knowledge in real-time.

OEE Based mostly on Human-Centric Information

The times of operating handbook time research are lengthy gone. When knowledge is acquired in real-time, the necessity to manually seize run time, changeover time, and different info is eradicated.

Human-centric knowledge can be error-prone, so even when the time is captured, the explanation could also be misunderstood or biased primarily based on the notion of the recorder. By capturing knowledge utilizing sensors and gadgets, the necessity for human enter is considerably diminished besides in instances the place it may be added to the automated knowledge seize within the type of contextualization.

This course of drives one of the best use utility the place some human-added knowledge is optimally captured for context points whereas leaving absolutely the knowledge seize to embedded sensors and gadgets.

The Components of OEE

OEE can be utilized successfully as a benchmark for measuring progress. OEE rating is calculated by multiplying its three components:

- Availability: Availability is measured utilizing deliberate and unplanned stops. Deliberate stops embrace changeovers, minor switchovers of settings, or software standing. Unplanned stops encompass breakdowns, jams, and shortages. A cease for both motive that causes an operator to log a motive code (or, within the case of automated machine monitoring, causes the system to log a cease motive) is an availability loss.

- Efficiency: Efficiency losses consequence when gear runs at lower than optimum velocity for that half specification. These losses encompass unavoidable loss, akin to that incurred upon startup, and course of loss, the place a course of is lower than optimized. Course of losses might consequence from gradual cycle occasions, small cease occasions, a damaged SOP, or coaching and upkeep points.

- High quality: High quality as an OEE ingredient refers back to the complete time used to provide high quality defects. This contains items that could be reworked to return to specification. The time used to provide the faulty half is subtracted from the entire time, lowering the OEE rating.

Calculation of OEE

OEE rating is calculated by multiplying three components collectively, Availability, Efficiency, and High quality. The calculation for the person components are:

- Availability = Run Time/Deliberate Manufacturing Time

- Efficiency = (Superb Cycle Time x Whole Depend)/Run Time

- High quality = Good Depend/Whole Depend

The easy calculation for OEE is:

- OEE = Availability x Efficiency x High quality

Or combining the calculations of the three components:

- OEE = (Good Depend x Superb Cycle Time)/ Deliberate Manufacturing Time

The best way to Use an OEE Dashboard

There are a number of dos and don’ts related to OEE dashboards.

Do

- Customise it to enterprise KPIs and person degree: As a result of they’re dynamic, real-time instruments, it is easy to configure easy dashboards that meet customers’ wants and help the production’s most important KPIs.

- Use insights to enhance decision-making: Machine monitoring sensors and gadgets join knowledge streams and permit evaluation that displays precise machine situation. Determination-makers have entry to reside conditions as they develop.

- Use OEE together with different metrics dashboards: OEE alone is not sufficient. Use it with different metric dashboards to uncover the higher worth of insights. This might be so simple as monitoring half counts.

- Drive course of enchancment and optimization: The insights delivered replicate machine efficiency and state, however in addition they supply a possibility to enhance.

Do not

- Ignore the information: Actual-time knowledge acquisition and evaluation eliminates errors, bias, and errors brought on by human intervention. Ignoring this info reduces the worth of the dashboard and lowers ROI.

- Restrict the worth of machine OEE: Study the completely different modes and views of the dynamic system. Leaving it on a plant or shift view signifies that the chance for constructive intervention can be missed.

- Use it as a disciplinary software: OEE is one in every of many machine monitoring metrics that may improve operational effectivity. Do not use it as a disciplinary software to divide. Use it as a software to coach, inspire, and enhance excellence.

Utilizing OEE Dashboards with MachineMetrics

MachineMetrics is a sturdy, best-in-class system for accumulating, standardizing, and taking motion on manufacturing knowledge. Out-of-the-box stories and dashboards, akin to real-time OEE dashboards. These dashboards are accessible at every machine, above the store ground, and in again places of work.

Utilizing the OEE dashboards from MachineMetrics, operators, technicians, and managers have entry to customizable and configurable knowledge that optimizes and streamlines operations. This real-time info is analyzed to collect insights that may be instantly used to take motion.

The system is versatile, permitting C suite execs and manufacturing unit ground operators entry to the identical info concurrently. This implies corporations can use these dashboards to make each tactical and strategic selections, with everybody working with a single model of the reality.

[ad_2]